Thank you for submission

Your message has been recievedand we will be contacting with you shortly to follow-up!

Suitable for all commonly used materials and geometries, and additionally can be used for shot blasting. Delivering parts ready for use or for other post- processing steps.

Machines gently clean large batches of parts in less than 10 minutes. Recipes and basket angles can be adjusted and stored, achieving reproducible results and maximum output.

Operator-friendly design configuration allows for a safer and more efficient user experience. Easy to install and use, CE certified.

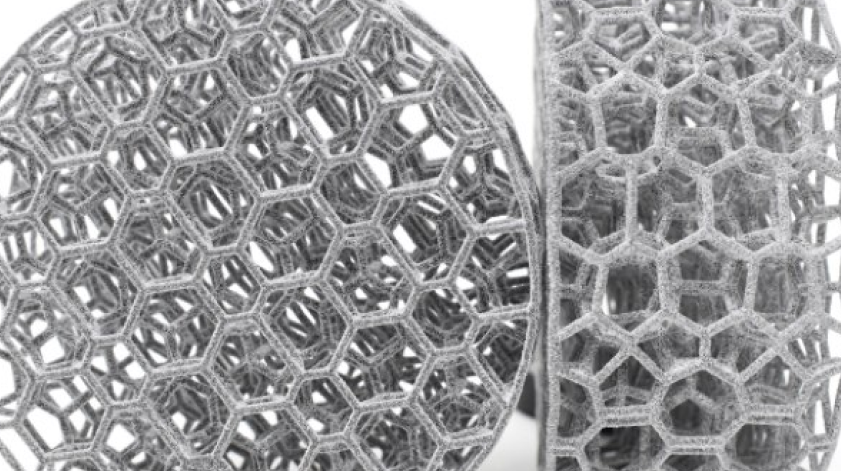

The vapor smoothing process completely seals the surface, making it airtight and watertight, eliminating liquid or gas intake

Tests have shown the reduction of bacteria growth and attachment on parts that have been chemically vapor smoothed

Due to the removal of surface porosity and crack initiation sites, extensive testing demonstrates that vapor smoothed parts results in an increase of Elongation at Break (EAB) with no loss in ultimate tensile strength

Using a series of predefined parameters our chemical vapor smoothing achieves for the first time a surface finish that matches injection molding techniques with an RA of less than 1 micron

The process does not degrade the mechanical properties of the parts. After vapor smoothing, parts exhibit no more than a 0,4%-dimensional change irrespective of the desired finish level.

E.g. pumps, pipes, tubes, inlets

E.g. electronics, semi-conductor

E.g. food processing, medical, dental

E.g. consumer products

Patented chemical vapor smoothing technology for improved aesthetics, color, mechanical properties and durability

Automated depowdering and shot blasting systems designed for low to high volume production

Patented chemical vapor smoothing technology for improved aesthetics, color, mechanical properties and durability

Automated depowdering and shot blasting systems designed for low to high volume production

Send us your samples and we will be happy to develop the best surface finishing process to achieve your processing goal.

59 Griva Digeni Kaimakliotis Building,

5th Floor 6043 Larnaca, Cyprus

Send us your samples and we will be happy to develop the best surface finishing process to achieve your processing goal.

Your message has been recievedand we will be contacting with you shortly to follow-up!